#Industry ·2024-09-22

A nitrogen protection UV system is a technical system that uses nitrogen to protect ultraviolet (UV) treatment processes in specific environments.

I. Working principle

Nitrogen is introduced into the treatment area while the UV system is operating. Its main function is to exclude oxygen, which can adversely affect the UV curing process. UV curing is usually initiated by ultraviolet radiation chemical reaction, so that specific materials quickly cured. Oxygen inhibits this reaction, reducing curing efficiency and quality. As an inert gas, nitrogen can effectively prevent the interference of oxygen and ensure the smooth progress of UV curing process.

II. System composition

1.Nitrogen supply device: including nitrogen storage tank, pressure reducing valve, flow meter, etc., used to provide stable nitrogen source and control the flow and pressure of nitrogen.

2.UV light source: Usually a high-intensity ultraviolet lamp or LED light source that produces ultraviolet light for curing.

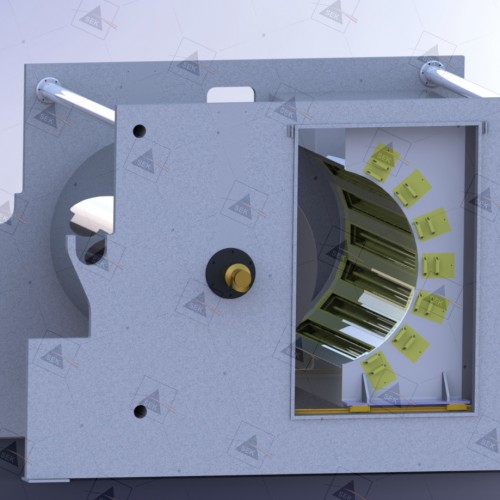

3.Reaction chamber: An area where the material to be treated is placed, and nitrogen forms a protective atmosphere in this area.

4.Control system: used to adjust and monitor nitrogen flow, UV light source intensity, temperature and other parameters to ensure stable operation of the system.

III. Application fields

1.Coating and ink industry: used for rapid curing of various coatings and inks, improve production efficiency and product quality. For example, in the printing industry, nitrogen protection UV systems can quickly dry ink on the surface of printed matter to avoid blocking and blurring.

2.Electronics industry: In the manufacturing process of electronic products, such as coating curing of circuit boards, connection of optical fibers, etc., nitrogen protection UV system can ensure high-precision curing effect and improve product reliability.

3.Optical industry: used to manufacture optical components, such as lenses, prisms, etc. Nitrogen protection prevents oxidation and contamination and ensures stability of optical properties.

4.Medical industry: In the production and packaging of medical devices, nitrogen protection UV systems can disinfect and cure products, improving product safety and hygiene standards.

IV. Advantages

1.Improve curing efficiency: eliminate oxygen interference, make UV curing reaction more rapid and complete, greatly shorten the curing time.

2.Improve product quality: reduce the poor curing phenomenon caused by oxygen, such as surface sticking, insufficient hardness, etc., improve the appearance quality and performance of the product.

3.Cost reduction: Due to the fast curing speed, production efficiency can be improved, energy consumption and labor costs can be reduced.

4.Adaptability: can be applied to a variety of different materials and process requirements, with a wide range of application prospects.

You can send us a general question inquiry here

0755-26420514

No. 58, Anfu Road, Panlongxuan, No. 73, Xinghua 2nd Road, Baomin Community, Xin'an Street, Bao'an District, Shenzhen

service@sekuv.com

WeChat customer

WeChat official

LINKS

0755-26420514

consult

top